Why Sweet Blossoms does not use floral foam

March 11, 2024

This post has been a long time coming. Sweet Blossoms has been foam free for years and vocally so, but I’ve never sat down and really verbalized all the reasons why. I think I can break down my reasons for not using floral foam into three categories: health, environment, and design.

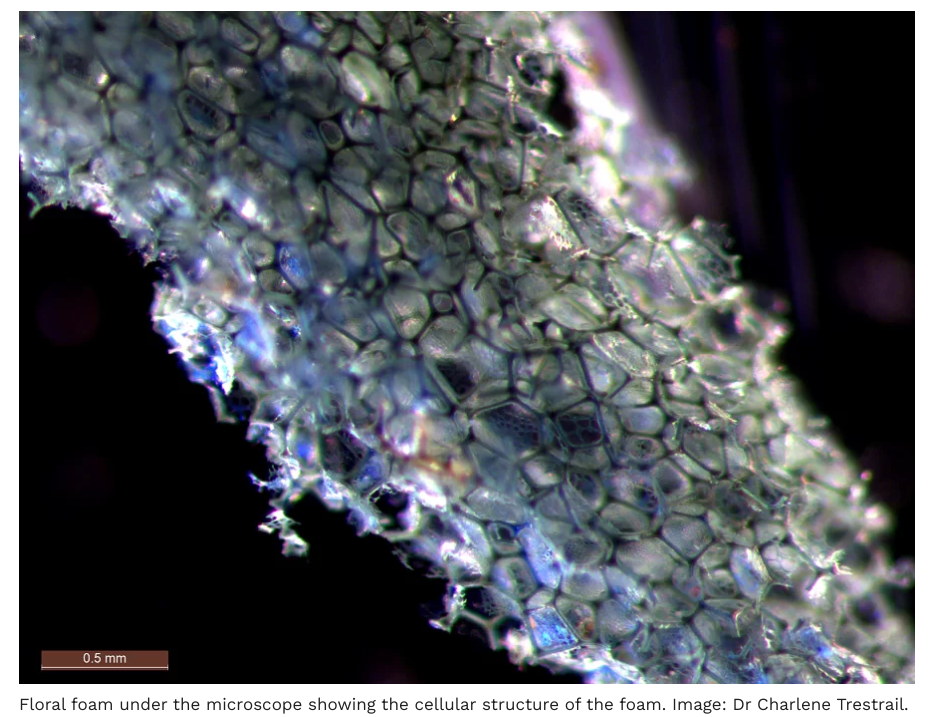

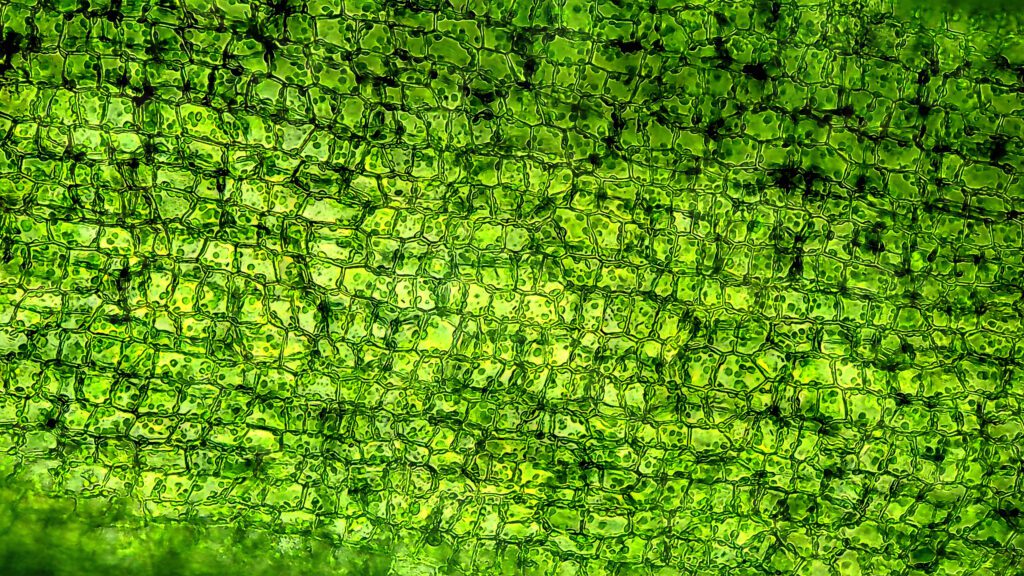

But first, what IS floral foam? Floral foam is a single use brick of microplastics in a honeycomb-like structure, which enables it to absorb and hold water for an extended period of time with the intent of both hydrating and holding flowers in place as a design mechanic. This type of structure allows water to be held in each chamber, which actually mirrors the structure of a plant cell.

Take a look at these two close-up images, side by side, below. See how similar they are in structure? Flowers left in floral foam can last for days, particularly if they are re-watered. It can be cut to fit any container and it comes in many different cages and saddles to suit various design needs. Floral foam is made from a family of plastics called phenol formaldehydes and also has trace amounts of carcinogens, which I will address in the next section.

Health

Floral foam has formaldehyde, carbon black, and phenol, among other things, on its ingredient list. All three of these are known carcinogens. Up until a few years ago, these ingredients were included in floral foam in higher quantities. Recently, the formula was changed, and now there is less than .1% of each of these ingredients, so floral foam receives a GHS rating of ‘not classified’ for toxicity and carcinogenicity.

If you’re thinking, isn’t this a good thing?? You’d be right. Yes, this is a really good thing. Reformulating a hazardous material to meet better standards is always a good thing. And if you listened to Oasis’ new PR campaign (more on that later), that information should be all you need to just buy foam again and start using it again, right?

Well, I think there are a few other health factors that could be considered.

The first is simply that foam still contains carcinogens, just less of them. So there’s that. Make your own decisions about whether or not you think that’s dangerous.

But the second, and possibly more relevant issue, is that floral foam is STILL made of plastic. In fact, it breaks down into tiny particles called microplastics. Anyone who has used foam before, knows that when it is dry, it gives off a dust, and even when it’s wet, it breaks down and has a gritty feeling on your hands that has to be washed off.

I can tell you as a seasoned florist who used to use foam and who has used it while freelancing in studios that still use it, that gritty dust hurts your eyes if you’re unlucky enough to touch your eyes. It will inflame any cut on your hands (and we all have them, whether it’s from snips, knives, or rose thorns, am I right?). It also turns my snot green because the particles are small enough to get inhaled (that’s right, read that again. I am talking about inhaling microplastics)!

So, I guess I don’t really care if it’s made of carcinogens or not because I FOR SURE don’t want microplastic dust in my eyes, cuts and lungs…

…carcinogen or not!

Environment

There is a larger conversation that needs to be had regarding the use of the word biodegradability. What does biodegradable mean? All biodegradable means is that something is able to be broken down into smaller particles by bacteria or other living organisms. The term is not regulated and there is no time limit for biodegradation. Did you know that everything will break down eventually, if given enough time, even glass and metal! If the product is a biodegradable plastic, it requires intense heat only available at industrial composting facilities and landfills in order to be able to properly break down into smaller parts.

Assuming the materials DO properly breakdown, most degraded plastics leave residues behind that are not helpful, it’s just smaller pieces of plastic: microplastics. More troubling, most conventional landfills aren’t even capable of providing the correct type of environment, so, oftentimes, people send their biodegradable plastics to the landfills, thinking they’ve done the right thing, and the product isn’t able to break down the way it’s supposed to.

Landfills also give off greenhouse gases created by the breakdown of these materials – yes, read that again. The products that are made to be eco-friendly end up giving off greenhouse gasses in the landfill.

Perhaps the picture is becoming clear: The term biodegradable has become a great way for companies to greenwash their products, since it’s an easy way to use an eco-friendly term and say true things about their product.

Most things DO biodegrade at some point, and there’s no regulation for whatever is left behind, so it’s easy to say something is biodegradable without meeting much of a standard. All biodegradable really means is that something breaks down into something smaller, and it doesn’t even have to be a smaller something that’s beneficial to our earth.

I think a relevant question to ask would be: Since most of this biodegradable material is headed for a landfill anyway, what’s really the point of it breaking down at all, if it’s still just breaking down in a trashbag in a landfill (and giving off greenhouse gases?). BUT….. biodegradable SOUNDS like a good eco-friendly word that people can put on labels, doesn’t it? So companies do.

And people buy more of it.

Back to the floral foam issue, most floral foam doesn’t even pretend to be biodegradable. There is one type of floral foam (Oasis MaxLife) that claims to be “degradable by 75% within one year in an anaerobic environment.” Degradable, not biodegradable. Here is a helpful document for distinguishing between some of these words. You’ll notice that materials that degrade simply degrade into smaller bits of the same thing (in this case plastic).

I have a few problems with this statement.

- It’s unlikely that the MaxLife foam will make it into the right kind of landfill to help it break down properly.

- Whether it breaks down or not, and however long it takes, it will likely emit greenhouse gases while it does this.

- We know it’s degrading into microplastics, not something that’s helpful to our earth.

And AGAIN, the question we should all be asking is, what real good is it doing to have this foam breaking down (again, into microplastics) in a landfill, if it’s still in a plastic trashbag with a bunch of other waste?

We’ve addressed the issue of floral foam that ends up in a landfill. But what about all the floral foam that goes down the drain? What happens to that foam? Typically when foam is soaked, it is soaked directly in a sink, or in a large container. When that process is done, the water is typically poured down the drain. Similarly, when arrangements with foam are thrown out, the remaining water is poured down the drain. I’ve even seen people wring out old foam (again, sending the excess water down the drain) before they put it in the trash in order to make the trash bags lighter! All this is to say, we are sending a LOT of microplastics down the drain, which goes straight into our groundwater and oceans.

This wonderful human was kind enough to dump their trash in the parking lot of a local wholesaler (who shall remain nameless). Look at the color of that water. It’s clearly floral foam water and there’s nowhere for that water to go but into the groundwater. With it, will go all the little bits of microplastics.

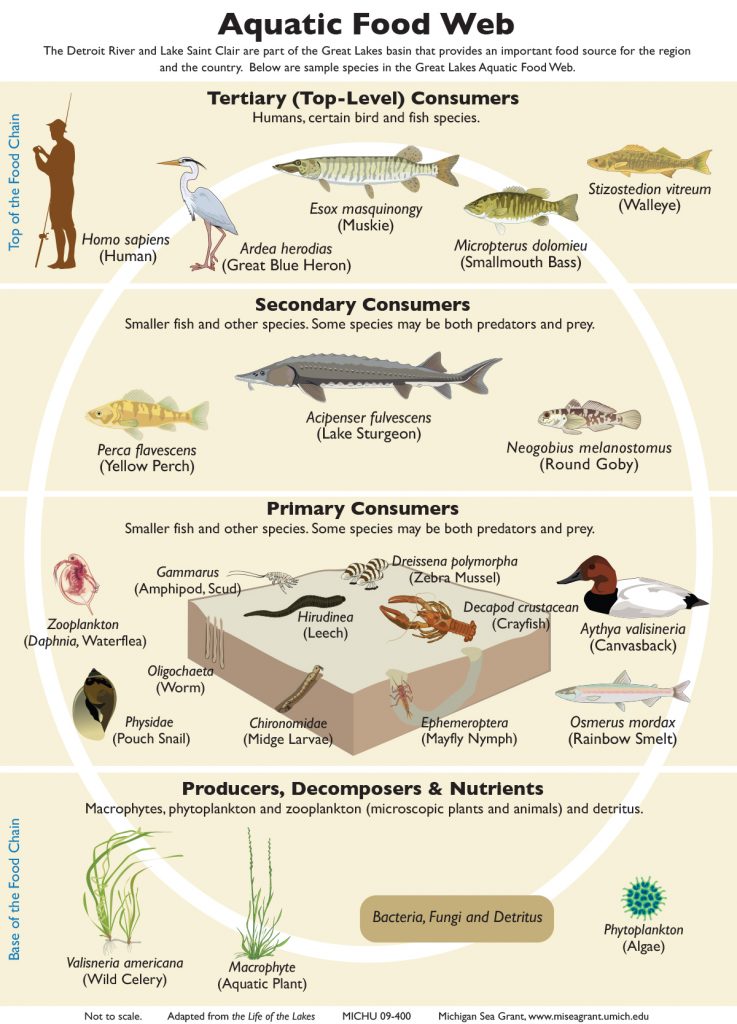

Here is a study in which both biofoam and regular floral foam was studied to see the effects of foam on aquatic invertebrates. Summarized, the study determined that floral foam microplastics get eaten by invertebrates and are even more toxic to them than other types of microplastics. These invertebrates are just the bottom of the foodchain. What do you think eats those invertebrates? Literally everything, up to and including humans!

The video below, from The Sustainable Floristry Network, does an amazing job of explaining the study in easy-to-understand terms, straight from the scientist’s mouth!

Here is a disturbing little study that was just published, in which scientists found that microplastics have now been found in all 62 placenta samples tested – a true full circle, as it pertains to the food chain.

Garcia said. “We’re not only getting it from ingestion but also through inhalation as well.”

(Remember what I said about not wanting to inhale the dust?)

Design

In the face of the health and environmental concerns, I’m not sure that the design flaws pertaining to floral foam are quite as urgent. But I will say that it’s my opinion that designing in foam does have some downsides. The first is that I find foam to be quite stiff. It holds the stem tightly, which does not allow for much free movement of the stem. The second is that foam has to be covered as a mechanic, and I find that covering up foam seems to take more product than having to cover other types of foam free mechanics. Lastly, if you want to remove a stem and place it elsewhere, you are left with a possible air pocket in the foam. If you were to insert another stem into this later on, you may inadvertently be inserting a stem into an “air pocket” instead of water, and then the stem doesn’t get enough water.

Since we are talking about design, I’ll take this opportunity to briefly touch on just one of my preferred foam free mechanics, since it addresses all three of these issues. Chicken wire and water in a vase allows for a stem to be placed in a vase, following the natural bends and lines of the stem. If the stem needs to bend a little to fit into the matrix of stems already in the vase, it can do so, because all the stems are able to move around inside the vase as well. For that matter, chicken wire rolls stuffed with moss or other branches/stems are my favorite mechanic for arches and installations. These can be stuffed with oshun pouches, agrawool or small water containers if you need a water source, or simply used as a matrix for reliable stems or water tubed stems. Best of all, all of this can be taken apart at the end of the night to be reused. Here are a few of my favorite foam free designs.

Just Say No

If you’re a florist, I totally get it, this is easier said than done. But, as best you can, this is obviously not something we want to be putting out into the environment with the kind of volume that event florists are capable of. My best advice is to start small, and eliminate only a few types of foam designs at a time. There are SO MANY resources and workshops out there now to help you get started. Click here to read more on how I’ve chosen to approach running a foam free and a low waste business. Whatever steps you’ve taken to remove ANY amount of foam from your studio, or do anything to make your studio more sustainable, those are all great steps that you can feel good about!

If you’re a consumer, a bride/groom, event host, retail shop client etc, you really have a lot of power! If it’s important to you to purchase designs that don’t have flower foam in them, you can request this from your florist! You can seek out shops and studios that are foam free, or you can at least request that your designs not be made with it. The more that florists see that consumers do not want to purchase this, the more florists will be further motivated to explore new design mechanics.

Here are some other resources that might be helpful.

- Sue McLeary foam-free online courses

- Flower Frogs – can be added to dip bowls for a pincup look, or vases to anchor your stems

- Floral pillows – can be reused on top of urns or in arch designs

- Oshun Pouches – a foam alternative. This company also sells bamboo cardette holders for retail shops!

- Sue McLeary also has a List of Reliables for foam free work

- The Sustainable Floristry Network

- Slow Flowers Society

- Afloral also has a helpful foam-free supply section

- School of Sustainable Floristry – if you feel like studying abroad

- Joseph Massie’s Wedding Masterclass is completely foam-free